WaterWeld is a specialized epoxy-based compound designed for sealing leaks and repairing cracks in wet or underwater environments; It’s ideal for plumbing, marine, and automotive repairs, offering durability and versatility.

What is WaterWeld?

WaterWeld is a versatile, epoxy-based compound specifically designed for sealing leaks and repairing cracks in wet or underwater environments. It is highly durable and adheres to a variety of surfaces, including metal, fiberglass, and plastic. Unlike traditional epoxy, WaterWeld can be applied to damp or submerged surfaces, making it ideal for plumbing, marine, and automotive repairs. Once cured, it becomes incredibly strong, capable of withstanding pressure and chemical exposure. WaterWeld is also paintable and can be drilled, tapped, or sanded for a seamless finish. Its unique properties make it a reliable solution for emergency repairs and long-term fixes alike, ensuring watertight seals in even the most challenging conditions.

Key Features and Benefits

WaterWeld is a highly versatile and durable epoxy compound designed for sealing leaks and repairing cracks in wet or underwater conditions. Its unique formula allows it to adhere to damp surfaces, making it ideal for plumbing, marine, and automotive repairs. Once cured, it forms a strong, waterproof bond that withstands pressure and chemical exposure. WaterWeld is also resistant to shrinking and cracking, ensuring long-lasting repairs. It can be drilled, tapped, filed, and sanded for a seamless finish and is compatible with a variety of materials, including metal, fiberglass, and plastic. Additionally, it can be painted, offering a cosmetically appealing solution. These features make WaterWeld an essential tool for emergency repairs and permanent fixes in challenging environments.

Safety Precautions

When using WaterWeld, ensure proper ventilation to avoid inhaling fumes. Wear protective gloves and eyewear to prevent skin and eye irritation. Avoid applying the product on open flames or sparks. Keep it away from children and pets. In case of skin contact, wash thoroughly with soap and water. If eye contact occurs, rinse with water for at least 15 minutes and seek medical attention. If ingested, do not induce vomiting and contact a poison control center immediately. Follow all instructions carefully to ensure safe and effective use. Store in a cool, dry place, away from direct sunlight and heat sources. Dispose of leftover material and packaging responsibly. Always refer to the Safety Data Sheet for detailed handling and safety guidelines.

Preparation

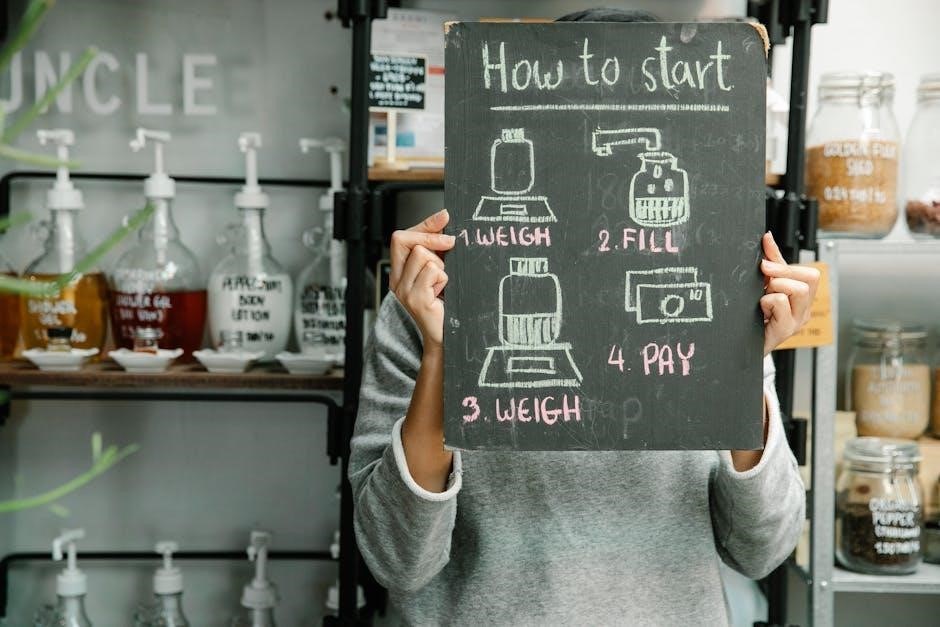

Before using WaterWeld, clean the surface thoroughly to ensure proper adhesion. Wear gloves to handle the compound effectively. Gather all necessary tools and materials beforehand.

Cleaning the Surface

Cleaning the surface is essential for successful WaterWeld application. Remove dirt, grease, or rust using sandpaper or a wire brush. For optimal results, ensure the area is dry and free of contaminants. This step ensures proper adhesion and durability of the repair. Using a mild detergent and water can also help, but allow the surface to dry completely before applying the compound. Proper preparation prevents failures and ensures long-lasting repairs. Avoid using harsh chemicals that might compromise the material. A clean, roughened surface enhances the bonding process, making the repair more effective and reliable over time. This step is crucial for both underwater and dry applications.

Mixing the Compound

Mixing WaterWeld requires careful attention to achieve the best results. Start by cutting off the desired amount from the stick. The compound is made of two components: a hardener and a resin. Knead the two parts together until they form a uniform color, ensuring there are no streaks. A 1:1 ratio is essential for proper curing. Overmixing can lead to a shorter workable time, so mix only what is needed for the repair. Once combined, the compound is workable for 15-25 minutes, depending on environmental conditions. Avoid adding more hardener than resin, as this can affect the product’s performance. Proper mixing ensures a strong, durable bond. Always wear gloves to prevent skin contact and work on a clean, disposable surface.

Application Instructions

Applying WaterWeld effectively requires a clean and prepared surface. Once mixed, press the compound firmly onto the area, ensuring full contact. For underwater repairs, apply quickly to prevent water interference. Smooth the edges to blend with the surrounding surface. Avoid over-applying, as this can lead to excess that may need sanding later. Use a gloved hand or tool to shape and press the compound into cracks or holes. For large areas, apply in thin layers, allowing each layer to set before adding more. Work in a well-ventilated area to avoid inhaling fumes. If the compound sticks to your gloves, use a small amount of water to help shape it. Proper application ensures a strong, lasting seal. Follow safety precautions to avoid skin contact and eye exposure.

Curing Process

WaterWeld begins curing in 15-25 minutes and reaches full strength in 1 hour. For optimal results, let it cure at room temperature (70-80°F) for 24 hours. Higher temperatures speed up curing, while lower temperatures slow it down. Once cured, it becomes waterproof and can withstand extreme conditions. After curing, the compound can be drilled, tapped, filed, sanded, and painted. Avoid disturbing the repair during the curing process, as this may weaken the bond. If applied underwater or in high humidity, ensure the surface is clean and free of standing water for proper adhesion. Full cure strength is achieved within 24 hours, making it durable for long-term repairs in plumbing, automotive, and marine applications. Proper curing ensures a strong, lasting seal.

Tools and Materials Needed

- A clean, dry surface to work on

- Gloves and safety goggles for protection

- A putty knife or similar tool for mixing and applying the compound

- Sandpaper or a wire brush for cleaning and roughening the surface

- Paper towels or a clean cloth for drying

- A mixing surface (e.g., a disposable board or plate)

- Measuring tools to ensure accurate mixing ratios

- WaterWeld epoxy compound

- Optional: clamps or a heat source for accelerated curing

Common Uses

WaterWeld is widely used for sealing leaks in pipes, repairing fuel tanks, fixing underwater cracks, and bonding materials like metal, plastic, and fiberglass in wet conditions.

Plumbing Repairs

WaterWeld is highly effective for sealing leaks in pipes, including PVC, copper, and iron. It works on wet surfaces, making it ideal for underwater or damp conditions. Apply it to patch holes, cracks, or faulty joints in plumbing systems. For best results, clean the area thoroughly before application. The compound adheres strongly to damp surfaces and cures underwater, ensuring a watertight seal. It’s perfect for emergency repairs or long-term fixes. Use it to seal drain leaks, repair pool equipment, or fix cracked shower pans. Its durability and resistance to water pressure make it a reliable solution for plumbing issues. Follow instructions carefully for proper mixing and application to achieve optimal results.

Automotive Repairs

WaterWeld is a versatile solution for various automotive repairs, particularly in wet or underwater conditions. It’s ideal for sealing leaks in fuel tanks, radiator leaks, and engine components. The compound adheres strongly to damp surfaces, making it perfect for repairing cracks or holes without draining the system. For best results, clean and roughen the surface before application. Once cured, it can be drilled, sanded, or painted, blending seamlessly with the surrounding material. WaterWeld is also suitable for repairing fiberglass and aluminum parts, common in automotive and marine applications. Its durability and resistance to water pressure make it a reliable choice for long-lasting repairs. Follow the mixing and application instructions carefully to ensure a strong, watertight seal.

Marine Repairs

WaterWeld excels in marine environments, providing durable solutions for underwater or wet repairs. It’s commonly used to fix leaks in boat hulls, fiberglass cracks, and aluminum surfaces. The compound adheres strongly to damp materials, making it ideal for sealing holes in fuel tanks or patching damaged areas without drying the surface. For optimal results, ensure the area is clean and free of grease or oil. Once cured, WaterWeld can withstand water pressure and harsh marine conditions. It’s also suitable for repairing bilges, drains, and other critical systems. Follow the application instructions carefully to achieve a watertight seal, ensuring your marine equipment remains functional and protected from further damage. Regular maintenance with WaterWeld can extend the lifespan of your marine gear.

Troubleshooting

If WaterWeld isn’t adhering properly, check if the surface is clean and free of grease or oil. Ensure the area is dry or slightly damp, as excessive moisture can hinder bonding. If the compound isn’t curing, verify that the mix is applied correctly and that the temperature is within the recommended range. High humidity or low temperatures can slow the curing process. For sticky or tacky surfaces, allow more time to cure or use a hairdryer on a low setting to speed up the process. If the repair fails, inspect the surface preparation and application steps. Improper mixing ratios or insufficient material may also cause issues. Reapply as needed, following the instructions carefully for optimal results. Always test a small area first to ensure compatibility with the material being repaired.

Comparing WaterWeld to Other Products

WaterWeld stands out among other repair compounds due to its ability to work effectively on wet or underwater surfaces, making it ideal for marine and plumbing repairs. Unlike some epoxies, it cures fully submerged, ensuring durable, long-lasting seals. While other products may require a dry surface, WaterWeld’s unique formula adapts to moist environments, providing versatility. Its curing time is comparable to similar compounds, with a set time of 15-25 minutes and full cure in 24 hours. However, its ability to bond to materials like PVC, metal, and fiberglass gives it an edge over general-purpose adhesives. Users often prefer WaterWeld for its ease of use and reliability in critical repairs, though it may not be as suitable for cosmetic or sculpting purposes. Its specialized design makes it a top choice for aquatic and high-moisture applications.

Environmental Considerations

WaterWeld is formulated to be safe for use on various materials, including PVC, metal, and fiberglass, without causing harm to pipes or the environment. It is non-toxic once cured, making it suitable for aquatic and plumbing applications. However, proper disposal of unused product and packaging is essential to minimize environmental impact. Users should avoid washing excess material down drains, as it can contaminate water systems. Clean-up should be done with appropriate solvents, following local regulations. The product’s durable bonding reduces the need for frequent repairs, lowering waste over time. While WaterWeld is effective in wet conditions, it is not biodegradable, so responsible handling and disposal are crucial to protect ecosystems.

Creative Uses Beyond Repairs

Beyond its primary function as a repair compound, WaterWeld can be used creatively in various DIY projects. For instance, it can be molded to create custom shapes or designs for arts and crafts. Some users have successfully used it to attach knife blades to handles, though it’s not ideal for intricate sculpting like Greenstuff or Milliput. Additionally, WaterWeld can be applied to create durable, waterproof coatings for outdoor furniture or marine equipment. Its strong adhesive properties make it suitable for bonding materials like fiberglass and aluminum, expanding its utility beyond traditional repairs. With some ingenuity, WaterWeld can become a versatile tool for both practical and creative applications, offering a reliable solution for unique projects.

Maintenance Tips

Regular maintenance is key to ensuring the longevity of repairs made with WaterWeld. After application, allow the compound to cure fully as per instructions to achieve maximum durability. Periodically inspect repaired areas for signs of wear or degradation, especially in high-stress environments; For underwater or marine repairs, consider applying a waterproof sealant or paint to protect the surface from further damage. In automotive or plumbing contexts, ensure the system is not under pressure until the compound has fully cured. Store leftover WaterWeld in a cool, dry place to maintain its effectiveness for future use. Proper care and inspection will help extend the life of your repairs.

WaterWeld is a versatile and reliable solution for a wide range of repair needs, from plumbing and automotive to marine applications. Its ability to adhere to wet surfaces and cure underwater makes it a trusted choice for emergency fixes and long-term durability. Whether you’re a professional or a DIY enthusiast, WaterWeld offers a user-friendly solution for sealing leaks and patching cracks. Proper preparation and application are key to achieving optimal results. With its strong curing properties and resistance to environmental factors, WaterWeld is an essential tool for anyone tackling repairs. Always follow the instructions carefully to ensure the best outcomes and longevity of your fixes.