trader joe’s pizza dough cooking instructions

Trader Joe’s Pizza Dough: A Comprehensive Cooking Guide

Unlocking delicious homemade pizza is easy with Trader Joe’s dough! This guide provides detailed instructions, from initial handling and resting techniques to optimal baking methods.

Understanding Trader Joe’s Pizza Dough

Trader Joe’s pizza dough is a convenient and affordable option for creating a delightful homemade pizza experience. It’s pre-made, refrigerated dough, typically found in a simple package, ready for your culinary creativity. Many appreciate its ease of use, bypassing the time-consuming process of making dough from scratch. However, understanding its characteristics is key to success.

The dough isn’t overly seasoned, providing a blank canvas for your favorite toppings. It’s important to note that it benefits significantly from proper handling and resting. Unlike some pre-made doughs, Trader Joe’s version requires a bit of coaxing to achieve a perfectly stretched and crispy crust. Initial shaping into a ball and allowing it to rest are crucial steps, as highlighted by many users.

Where to Find It in the Store

Locating Trader Joe’s pizza dough within the store is generally quite straightforward, though its exact placement can vary slightly depending on the store layout. Typically, you’ll find it in the refrigerated section, specifically within the fresh pasta and dough area. Look near the pre-made pasta, cheeses, and other refrigerated Italian-style foods.

It’s often stocked alongside other refrigerated doughs, such as cookie dough or crescent roll dough. However, it’s not always in the same aisle as frozen pizzas. Be prepared to check multiple refrigerated sections if you don’t spot it immediately. Stock levels can fluctuate, especially on weekends, so it’s wise to visit during off-peak hours for the best chance of finding it readily available.

The Dough’s Ingredients and Composition

Trader Joe’s pizza dough boasts a relatively simple ingredient list, contributing to its appealing taste and texture. The primary components include wheat flour, water, yeast, olive oil, and salt. Notably, it doesn’t contain any artificial flavors, preservatives, or high fructose corn syrup, aligning with Trader Joe’s commitment to cleaner ingredient lists.

The dough’s composition results in a slightly chewy, yet tender crust when baked correctly. The presence of olive oil contributes to its flavor and helps achieve a desirable texture. While the exact flour type isn’t specified, it appears to be a standard bread flour, providing sufficient gluten development for a good rise and structure. This straightforward composition makes it a versatile base for various pizza creations.

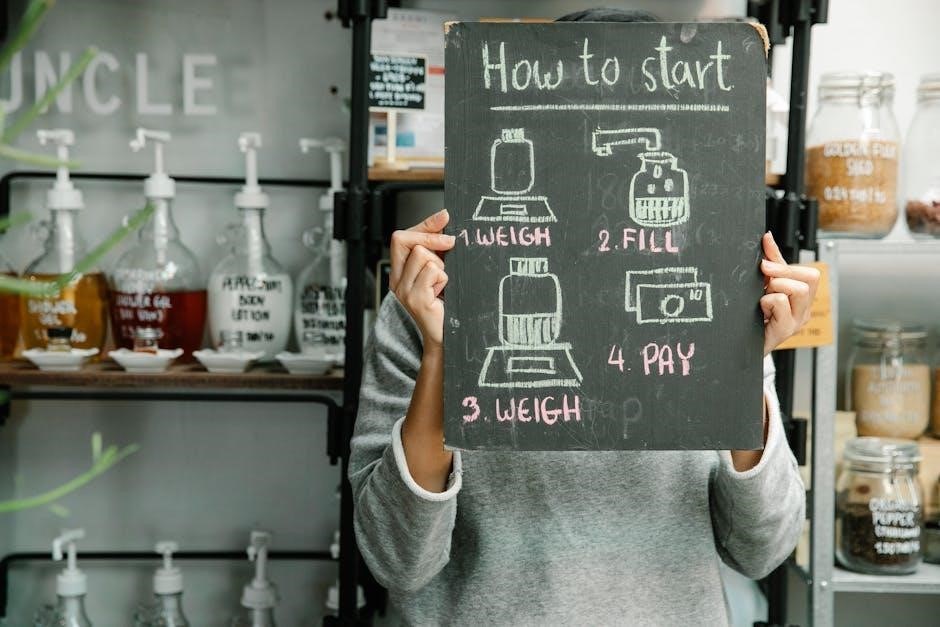

Preparing the Dough for Cooking

Proper preparation is key! Gently form the dough into a ball, rest it for at least 30 minutes, and utilize olive oil for easier handling.

Initial Dough Handling: Forming a Ball

Beginning with the Trader Joe’s pizza dough, the first crucial step is removing it from its packaging. Many sources recommend immediately forming the dough into a smooth, tight ball. This process isn’t about aggressive kneading; instead, gently coax the dough together, tucking the edges underneath to create surface tension.

This initial shaping helps develop gluten structure, leading to a more pliable and easier-to-work-with crust. Avoid excessive flour during this stage, as it can dry out the dough. A lightly oiled surface can be beneficial. Forming a ball allows for even resting and expansion, ultimately contributing to a better texture and overall pizza experience. Don’t overwork it!

Resting the Dough: Timing and Techniques

Allowing the Trader Joe’s pizza dough to rest is paramount for achieving a tender, flavorful crust. A minimum 30-minute rest at room temperature is generally recommended, though some bakers suggest an overnight rest in the refrigerator for enhanced flavor development. During this time, gluten relaxes, making the dough easier to stretch and preventing it from snapping back.

Cover the dough ball loosely with plastic wrap or a damp towel to prevent drying. Resting on a lightly oiled surface, rather than a floured one, is often advised to maintain moisture. Patience is key; a well-rested dough yields a superior pizza!

Using Olive Oil for Easier Handling

Trader Joe’s pizza dough can sometimes be a bit sticky, making it challenging to work with. A simple solution is to utilize olive oil! Instead of heavily flouring your work surface, lightly coat it with olive oil. This creates a non-stick barrier, preventing the dough from adhering and allowing for smoother stretching and shaping.

Additionally, lightly oiling your hands can further aid in handling. The olive oil not only improves manageability but also contributes to a richer flavor and a beautifully golden-brown crust. Don’t overdo it – a light coating is all you need for success!

Cooking Methods: Oven Baking

Oven baking delivers classic pizza results! Preheat your oven, prepare your baking surface, and follow time guidelines for a perfectly cooked, golden-brown Trader Joe’s pizza.

Optimal Oven Temperature

Achieving the ideal oven temperature is crucial for a fantastic Trader Joe’s pizza. Most sources recommend a high heat, typically between 425°F (218°C) and 450°F (232°C). This elevated temperature mimics the conditions of a traditional pizza oven, promoting a crispy crust and well-melted toppings.

Preheating your oven thoroughly is essential – allow at least 30 minutes for it to reach the desired temperature. A hotter oven ensures a quicker bake, preventing the dough from becoming soggy. Some bakers even suggest using the oven’s broiler for the last minute or two to achieve extra browning and bubbling on the cheese. Experiment to find what works best with your oven!

Remember that oven temperatures can vary, so monitoring your pizza closely during baking is always a good idea.

Baking Time Guidelines

Determining the correct baking time for Trader Joe’s pizza dough depends on your oven temperature and desired crust thickness. Generally, a baking time of 12-15 minutes at 425°F (218°C) to 450°F (232°C) is a good starting point.

Keep a close watch on the pizza during the last few minutes of baking. The crust should be golden brown and slightly crisp, and the cheese should be melted and bubbly. Rotating the pizza halfway through baking can help ensure even cooking.

If you prefer a thinner crust, reduce the baking time slightly. For a thicker, chewier crust, you may need to add a few extra minutes. Always check for doneness before removing the pizza from the oven!

Using a Pizza Stone or Baking Sheet

For a truly crispy crust, a pizza stone is highly recommended! Preheat the stone in the oven during preheating, ensuring it’s thoroughly heated before placing the pizza on it. Carefully slide the prepared pizza onto the hot stone using a pizza peel dusted with cornmeal.

If you don’t have a pizza stone, a baking sheet will work just fine. Lightly grease the baking sheet with olive oil or line it with parchment paper to prevent sticking. Transfer the stretched dough to the prepared baking sheet before adding toppings.

Baking directly on the stone yields a superior crust, but a baking sheet provides convenience and ease of handling.

Cooking Methods: Alternative Techniques

Beyond oven baking, Trader Joe’s dough excels on the grill or in a skillet! These methods offer unique textures and flavors for a quick, delicious meal.

Grilling the Pizza Dough

Grilling Trader Joe’s pizza dough imparts a smoky flavor and delightfully charred texture. Begin by preheating your grill to medium-high heat. Lightly oil the grill grates to prevent sticking. Gently stretch or roll the dough to your desired thickness and carefully place it directly onto the hot grill.

Grill for approximately 2-3 minutes per side, watching closely to avoid burning. The dough should develop grill marks and become slightly puffed. Remove from the grill and quickly add your desired toppings. Return the pizza to the grill, close the lid, and cook for another 2-5 minutes, or until the cheese is melted and bubbly and the toppings are heated through. This method creates a wonderfully crispy crust with a unique, summery taste!

Skillet/Pan-Frying the Dough

For a quick and easy pizza experience, skillet or pan-frying Trader Joe’s dough delivers a wonderfully crispy base. Heat a tablespoon of olive oil in a large skillet over medium heat. Gently stretch or roll the dough to fit the skillet’s diameter. Carefully place the dough in the hot oil and cook for 3-4 minutes per side, until golden brown and slightly puffed.

Remove the partially cooked crust from the skillet and flip it over. Add your favorite sauce and toppings to the cooked side. Cover the skillet and continue cooking for another 5-7 minutes, or until the cheese is melted and the toppings are heated through. This method creates a delightfully crunchy crust, perfect for a weeknight meal!

Topping Suggestions and Considerations

Elevate your pizza! Use sauce sparingly to avoid sogginess, and don’t overload toppings. Trader Joe’s offers fantastic pairings for a flavorful experience.

Sauce Quantity: Avoiding a Soggy Crust

Achieving a perfectly crisp crust with Trader Joe’s pizza dough hinges on mindful sauce application. A common pitfall is using too much sauce, leading to a soggy, unstable base. Remember, less is often more! Begin with a thin, even layer, spreading it deliberately but sparingly across the dough.

Consider the sauce’s moisture content; some varieties are wetter than others. A good starting point is approximately ¼ to ⅓ cup for a standard-sized Trader Joe’s dough ball. Avoid extending the sauce all the way to the edges, leaving about a half-inch border for the crust to develop properly. This creates a natural barrier, preventing the sauce from seeping into the outer edges during baking and compromising their crispness.

Experiment to find your ideal sauce-to-dough ratio, but always prioritize a lighter touch to ensure a delightful, structurally sound pizza.

Topping Weight: Preventing Overload

Maintaining structural integrity is crucial when topping your Trader Joe’s pizza. Overloading the dough with too many ingredients can result in a floppy, difficult-to-handle pizza, and potentially a burnt or undercooked crust. Distribute toppings evenly, avoiding large, concentrated piles.

Heavier toppings, like copious amounts of cheese or dense vegetables, should be used more sparingly. Consider pre-cooking vegetables with high water content to reduce moisture release during baking. A balanced approach is key – aim for a harmonious blend of flavors and textures without overwhelming the dough’s capacity.

Remember, the dough is relatively thin, so restraint is vital. Prioritize quality over quantity, selecting complementary toppings that enhance, rather than hinder, the pizza’s overall structure and bake.

Popular Trader Joe’s Topping Pairings

Trader Joe’s offers a fantastic array of ingredients perfect for pizza night! A classic combination is the store’s marinara sauce paired with fresh mozzarella, basil, and pepperoni. For a more adventurous palate, try the Calabrian chili pasta sauce with spicy Italian sausage and roasted red peppers.

The unexpected pairing of fig jam, prosciutto, and goat cheese creates a sweet and savory delight. Don’t overlook the pre-shredded cheeses – the three-cheese blend is a versatile option. Utilize the store’s unique pesto varieties for a vibrant, flavorful base.

Experiment with seasonal produce like butternut squash or Brussels sprouts for a unique twist. Remember to complement the dough’s flavor with thoughtfully chosen ingredients!

Troubleshooting Common Issues

Sticky dough can be solved with flour; tough crusts need less handling. Uneven baking? Rotate the pizza during cooking for consistent results!

Dealing with Sticky Dough

Trader Joe’s pizza dough can sometimes be surprisingly sticky, making it challenging to work with. Don’t panic! The key is to avoid over-flouring, which can alter the dough’s texture. Instead, lightly oil your work surface with olive oil – this creates a non-stick barrier without drying out the dough.

As you handle the dough, keep your hands lightly oiled as well. If it still sticks, sprinkle a very small amount of flour onto your hands and the dough, incorporating it gently. Resist the urge to add a lot of flour at once, as this can make the crust tough. Patience and a gentle touch are crucial. Remember, a slightly sticky dough often yields a chewier, more flavorful crust!

Preventing a Tough Crust

A tough pizza crust is a common frustration, but easily avoidable with Trader Joe’s dough. Overworking the dough is the primary culprit; handle it gently and avoid excessive kneading. Allow sufficient resting time – at least 30 minutes, or even overnight in the refrigerator – to allow the gluten to relax.

Using olive oil during handling also helps maintain tenderness. When stretching the dough, avoid using a rolling pin, as this compresses the air bubbles. Instead, gently stretch it with your hands. Finally, avoid overloading the pizza with toppings, as excessive weight can also contribute to a dense, tough crust. A lighter touch yields a delightfully airy result!

Addressing Uneven Baking

Uneven baking can occur when using Trader Joe’s pizza dough, often due to inconsistent oven temperatures. Utilizing a pizza stone preheated in the oven for at least 30 minutes helps distribute heat more evenly. If you don’t have a stone, a preheated baking sheet works, but may require slightly longer baking times.

Rotating the pizza halfway through baking ensures all sides receive equal exposure to the heat. Also, ensure your oven rack is positioned in the center. If one area consistently browns faster, try shielding it with foil. Monitoring closely and adjusting baking time accordingly will result in a perfectly golden, evenly baked pizza every time!

Advanced Techniques

Elevate your pizza game with cold fermentation for deeper flavor! Experiment with stretching techniques and create thin or thick crusts to personalize your experience.

Cold Fermentation for Enhanced Flavor

Unlock a more complex and nuanced flavor profile in your Trader Joe’s pizza dough through cold fermentation. This technique involves a prolonged, slow rise in the refrigerator. After forming your dough into a ball, place it in a lightly oiled container, cover tightly, and refrigerate for 24 to 72 hours.

The extended cold rest allows enzymes to break down starches and proteins, developing richer, more savory flavors. Don’t worry about the dough rising significantly; the goal is flavor development, not substantial volume increase. When ready to bake, remove the dough from the refrigerator about 30-60 minutes before stretching to allow it to warm up slightly, making it more pliable. This method truly transforms the Trader Joe’s dough!

Stretching the Dough: Tips and Tricks

Achieving the perfect pizza base starts with proper dough stretching. Gently coax the dough outwards, using your fingertips to press and stretch from the center. Avoid using a rolling pin, as it compresses the dough, resulting in a tougher crust. Lift the dough and gently stretch it over the backs of your hands, rotating as you go.

If the dough resists stretching, let it rest for another 5-10 minutes to allow the gluten to relax. Dust your work surface lightly with flour or, even better, semolina flour to prevent sticking. Aim for a roughly 12-14 inch circle, leaving a slightly thicker edge for the crust. Practice makes perfect – don’t be discouraged if your first attempt isn’t flawless!

Creating Different Crust Styles (Thin, Thick)

Trader Joe’s dough is versatile, allowing for varied crust styles. For a thin, crispy crust, stretch the dough more extensively, aiming for a larger diameter – around 14-16 inches. Use minimal sauce and toppings to prevent sogginess. A higher oven temperature (450-475°F) also promotes crispness.

To create a thicker, chewier crust, stretch the dough to a smaller size (10-12 inches) and leave it slightly thicker at the edges. Don’t overwork the dough during stretching. A slightly lower oven temperature (425-450°F) and a longer baking time will ensure the center cooks through without burning the crust. Experiment to find your preferred style!

Storage and Preservation

Leftover dough can be refrigerated for a day or two, or frozen for longer storage. Thaw frozen dough slowly in the refrigerator for best results.

Refrigerating Leftover Dough

If you find yourself with leftover Trader Joe’s pizza dough after a satisfying pizza night, proper refrigeration is key to maintaining its quality. Immediately after use, place the dough in an airtight container or a resealable plastic bag. Ensure the container is lightly coated with olive oil to prevent sticking and drying.

Refrigerated dough will generally remain usable for up to two days, though its texture may slightly change. Before using refrigerated dough, allow it to come to room temperature for approximately 30-60 minutes. This will make it more pliable and easier to stretch. Don’t be alarmed if it needs a little extra flour during stretching, as the chilling process can affect its elasticity. Properly refrigerated dough offers a convenient option for a quick weeknight pizza!

Freezing Trader Joe’s Pizza Dough

For longer-term storage, freezing Trader Joe’s pizza dough is an excellent option. Divide the dough into portions corresponding to the size of pizzas you typically make. This allows for convenient thawing of only what you need. Wrap each portion tightly in plastic wrap, ensuring no air pockets remain.

Follow this by placing the wrapped dough inside a freezer-safe bag or container. Properly frozen, the dough can last for up to two months without significant quality loss. When ready to use, transfer the frozen dough to the refrigerator and allow it to thaw slowly overnight. This gradual thawing process yields the best results for texture and ease of handling.

Thawing Frozen Dough Properly

Proper thawing is crucial for achieving the best texture with frozen Trader Joe’s pizza dough. The recommended method is a slow, overnight thaw in the refrigerator. This allows the dough to regain its elasticity gradually, preventing a gummy or tough final product. Remove the frozen dough from the freezer and place it in a lightly oiled bowl, covered with plastic wrap.

Alternatively, for quicker thawing, you can place the dough in a sealed bag and submerge it in cold water, changing the water every 30 minutes. However, refrigerator thawing is preferred. Once thawed, allow the dough to come to room temperature for about 30 minutes before shaping and baking.