Steam boiler piping diagrams provide a visual representation of boiler systems, ensuring proper installation, safety, and efficiency. They guide technicians through complex setups, adhering to ASME standards.

1.1 Importance of Steam Boiler Piping Diagrams

Steam boiler piping diagrams are essential for ensuring safe and efficient boiler operation. They provide a clear visual guide for installing, maintaining, and troubleshooting boiler systems. These diagrams help technicians understand the flow of steam and condensate, ensuring proper connections and compliance with safety standards. By following piping diagrams, potential hazards like leaks or pressure imbalances can be minimized. They also serve as a reference for meeting ASME standards and local codes, ensuring system reliability and longevity. Proper piping layouts are crucial for optimal performance, making these diagrams indispensable for both installation and ongoing maintenance of steam boiler systems.

1.2 Benefits of Using Piping Diagrams for Steam Boilers

Using piping diagrams for steam boilers offers numerous benefits, including improved system efficiency and reduced installation errors. These diagrams simplify the understanding of complex piping layouts, ensuring compliance with ASME standards and local regulations. They also aid in identifying potential issues like leaks or pressure drops early, minimizing downtime. Additionally, piping diagrams provide a clear guide for maintenance and troubleshooting, helping technicians optimize system performance. By following these diagrams, installations become faster and more accurate, ensuring safety and reliability. Overall, they are invaluable tools for maintaining the integrity and functionality of steam boiler systems, making them a cornerstone of boiler management and operation.

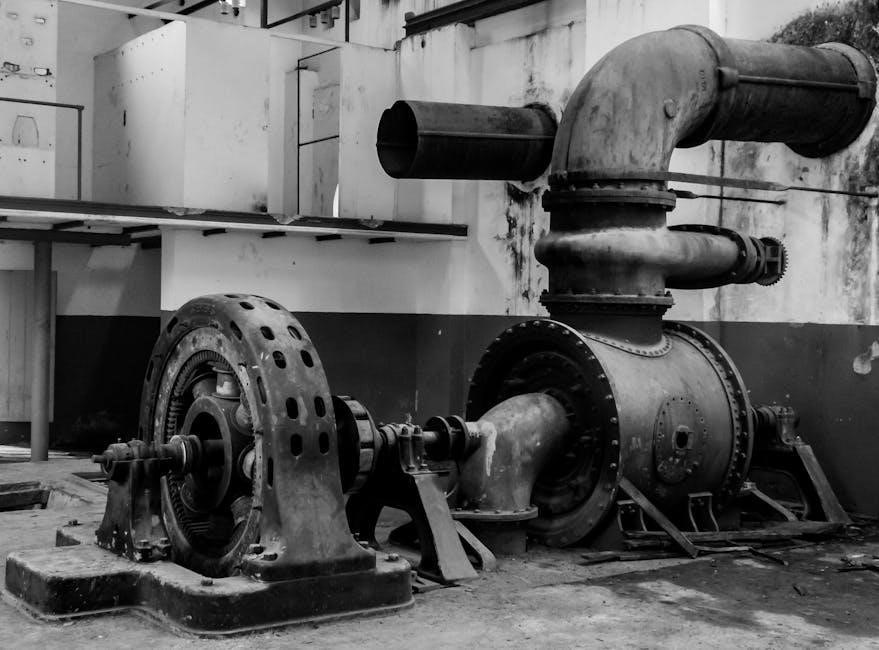

Key Components of a Steam Boiler Piping Diagram

Steam boiler piping diagrams include essential components like headers, returns, and vents. They also detail connections for safety valves, feedwater systems, and condensate returns, ensuring proper system functionality.

2.1 Boiler Header Connections

Boiler header connections are critical for steam distribution and water return. The header must be at least 24 inches above the water line, as shown in diagrams. Proper sizing ensures efficient steam flow, while incorrect sizing can lead to system inefficiencies. Connections should be one pipe size larger than direct boiler piping to accommodate steam velocity. Primary headers should be 4-pipe systems, ensuring balanced distribution. These configurations prevent pressure drops and ensure even steam supply, adhering to ASME standards for safety and performance.

2.2 Piping Configurations for Single and Multiple Boilers

Piping configurations vary for single and multiple boiler systems. Single boilers use direct header connections, while multiple boilers require primary and secondary headers to balance steam distribution. Each configuration ensures proper steam flow and pressure. For multiple boilers, primary headers collect steam, and secondary headers distribute it, preventing pressure drops. Diagrams illustrate one-pipe and two-pipe systems, guiding installers. Proper sizing and spacing are crucial for efficiency and safety, adhering to local codes and ASME standards. These configurations optimize performance and reliability in steam boiler systems, ensuring even heat distribution and minimizing potential issues.

Understanding Steam Boiler Piping Layouts

Steam boiler piping layouts involve primary and secondary systems, ensuring proper steam flow and condensate return. Sizing and spacing are critical for efficiency and safety.

3;1 Sizing and Spacing of Pipes

Proper sizing and spacing of pipes are crucial for efficient steam flow and system performance. Undersized pipes can lead to pressure drops, while oversizing may cause condensation issues. Pipes should be spaced adequately to accommodate thermal expansion and ensure accessibility for maintenance. The primary header should be at least one pipe size larger than direct boiler connections, and the distance between pipes must align with ASME standards. Correct sizing ensures uniform steam distribution, while proper spacing prevents damage from heat and vibration, adhering to manufacturer guidelines and safety protocols for optimal boiler operation.

3.2 Primary and Secondary Piping Systems

Steam boiler systems utilize primary and secondary piping to ensure efficient steam distribution and condensate return. The primary system connects directly to the boiler, distributing steam to main lines, while secondary pipes branch off to individual equipment or rooms. Proper design ensures minimal pressure drops and balanced flow. Primary headers should be sized one pipe diameter larger than direct boiler connections, and secondary lines must maintain consistent sizing to prevent condensation accumulation. This dual-system approach enhances reliability, reduces energy losses, and ensures optimal performance across the entire steam network, as detailed in ASME standards and manufacturer guidelines for piping layouts.

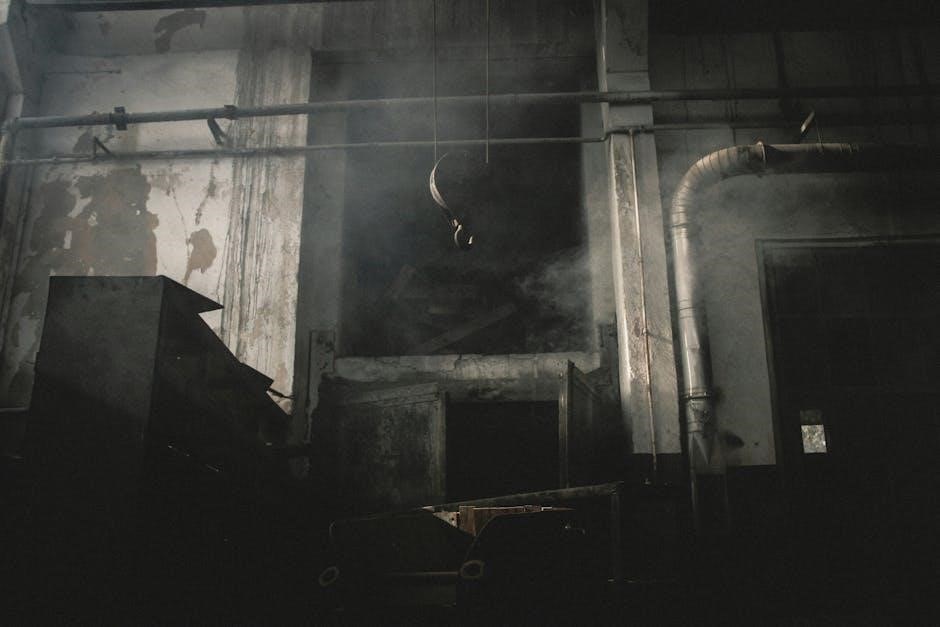

Venting and Safety Considerations

Proper venting prevents gas buildup and ensures safe operation. Safety valves release excess pressure, protecting the system. Compliance with local codes and manufacturer guidelines is essential for efficiency and safety.

4.1 Proper Venting for Steam Boilers

Proper venting is critical for steam boilers to ensure efficient operation and safety. The venting system removes combustion gases and prevents pressure buildup. Use 28-gauge galvanized pipes for durability and corrosion resistance. The flue should be sized correctly, and its location must comply with local codes. Ensuring a proper venting setup prevents backdrafts and maintains optimal boiler performance. Regular inspections are necessary to identify and address any issues, such as blockages or leaks. Proper venting also reduces the risk of carbon monoxide hazards, ensuring a safe environment for the boiler system and its surroundings. Compliance with ASME standards is mandatory for venting configurations.

4.2 Safety Valves and Their Placement

Safety valves are essential for steam boilers to relieve excess pressure and prevent potential explosions. They must be installed in accordance with ASME standards, ensuring proper sizing and placement. The valve should be positioned vertically, with the discharge piped away safely. Regular testing and inspection are crucial to ensure reliability. The placement must avoid obstructions and ensure easy access for maintenance. Correct installation and compliance with standards are vital to maintain system integrity and operator safety. Properly functioning safety valves are a cornerstone of steam boiler safety, protecting both equipment and personnel from hazardous pressure buildup.

ASME Standards for Boiler Piping

ASME standards ensure boiler piping systems meet safety and quality requirements. Section 1 specifies piping materials, sizes, and configurations, while approved fittings and valves guarantee compliance and reliability.

5.1 Compliance with Section 1 Piping Requirements

Compliance with ASME Section 1 ensures piping systems meet rigorous safety and design standards. Materials, sizes, and configurations must align with specified requirements. Boiler headers, connections, and fittings are carefully detailed to prevent failures. The header must be at least 24 inches above the water line, as shown in diagrams. Approved valves and instruments are essential for safe operation. Proper sizing and placement of safety valves are mandated to handle pressure relief effectively, ensuring system integrity and operator safety. Adherence to these standards is critical for reliable and efficient steam boiler performance.

5.2 Fittings and Valves Approved by ASME

Fittings and valves in steam boiler systems must meet ASME standards for safety and reliability. These components are specifically designed to withstand high pressures and temperatures. ASME approval ensures materials and manufacturing processes are up to code. Proper sizing and installation of valves, such as safety and relief valves, are critical to prevent system failures. Approved fittings, including elbows, tees, and reducers, maintain structural integrity. Manufacturer-supplied components are recommended to guarantee compliance. Correct installation, including the use of Teflon tape and pipe dope, ensures leak-free connections, adhering to ASME guidelines for safe and efficient boiler operation.

Installation and Maintenance Tips

Ensure correct gas supply, fresh air, and electrical connections. Properly vent boilers and follow ASME standards for safe, efficient operation and long system life.

6.1 Connecting Boiler to Venting and Piping Systems

Proper connection of the boiler to venting and piping systems is crucial for safe and efficient operation. Ensure vent pipes are correctly sized and installed according to ASME standards. Use high-quality materials like galvanized pipes to prevent corrosion. The boiler header should be at least 24 inches above the water line to maintain proper steam flow. Apply Teflon tape and pipe dope on threaded connections for leak-proof sealing. Always follow local codes and manufacturer guidelines for installation to avoid potential hazards and ensure optimal performance.

6.2 Regular Inspection of Piping and Fittings

Regular inspection of piping and fittings is essential for maintaining steam boiler efficiency and safety. Check for leaks, corrosion, and secure connections. Ensure vent pipes are sized correctly and installed according to ASME standards. Apply Teflon tape and pipe dope to threaded connections for tight seals. Regular maintenance prevents system failures, reduces downtime, and ensures compliance with safety standards. Always follow local codes and manufacturer guidelines to uphold system integrity and optimal performance.

Troubleshooting Common Piping Issues

Identify leaks, corrosion, and pressure drops in steam boiler piping systems. Ensure proper venting and pipe sizing to prevent system inefficiencies and potential hazards.

7.1 Identifying Leaks and Corrosion

Leaks and corrosion in steam boiler piping systems can lead to significant inefficiencies and safety hazards. Regular inspections are crucial to detect these issues early. Look for water droplets, rust stains, or unusual noises indicating leaks. Corrosion often results from moisture, chemical exposure, or poor pipe quality. Use visual checks and pressure testing to identify compromised areas. Addressing these problems promptly prevents system failures and ensures optimal performance. Neglecting leaks and corrosion can lead to costly repairs and downtime. Proper maintenance and material selection are essential for long-term reliability.

7.2 Addressing Pressure Drops in the System

Pressure drops in steam boiler piping systems can reduce efficiency and cause operational issues. Common causes include undersized pipes, excessive fittings, or blockages; To address this, ensure proper sizing of pipes according to ASME standards. Minimize fittings and check for obstructions like debris or scale buildup. Regular cleaning and maintenance can prevent pressure losses. Additionally, installing pressure-regulating valves can help stabilize the system. Monitoring pressure gauges and comparing readings with design specifications aids in identifying discrepancies. Correcting pressure drops ensures consistent steam flow, optimal heat transfer, and overall system performance.

Steam boiler piping diagrams are essential for ensuring safety, efficiency, and compliance with ASME standards. Proper installation, venting, and maintenance are crucial for optimal performance.

8.1 Summary of Best Practices

Adhering to ASME standards ensures compliance and safety in steam boiler piping. Proper venting and pipe sizing are critical for efficient operation. Regular inspections of pipes, fittings, and safety valves prevent leaks and corrosion. Maintaining a minimum 24-inch header height above the water line is essential. Use approved materials and fittings to avoid system failures. Always follow local codes and manufacturer guidelines for installation. Properly connect boilers to venting and piping systems, ensuring adequate allowances for expansion. Regular maintenance and adherence to best practices optimize performance and longevity of the steam boiler system.

8.2 Final Thoughts on Steam Boiler Piping Diagrams

Steam boiler piping diagrams are indispensable tools for ensuring safe, efficient, and compliant boiler operations. They provide clear guidance for installers and technicians, helping to avoid common pitfalls. Properly designed diagrams simplify maintenance and troubleshooting, reducing downtime. By adhering to ASME standards and best practices, users can optimize system performance and longevity. Continuous learning and adaptation to new technologies are essential for mastering steam boiler piping systems. These diagrams serve as the foundation for achieving peak efficiency, safety, and reliability in industrial and commercial steam boiler applications.