six sigma yellow belt exam questions and answers pdf

This PDF guide provides a comprehensive collection of Six Sigma Yellow Belt exam questions and detailed answers, helping candidates prepare effectively for their certification․ It includes over 100 sample questions covering various topics, from basic principles to advanced tools, ensuring a thorough understanding of the exam format and content․ Ideal for those new to Six Sigma, this resource offers insights into Lean Six Sigma methodologies and practical applications, making it an essential tool for achieving certification and improving process management skills․

Overview of Six Sigma and the Yellow Belt Certification

Six Sigma is a data-driven methodology aimed at process improvement and defect reduction․ Originating at Motorola, it has become a global standard for operational excellence․ The Yellow Belt certification is an entry-level credential designed for individuals new to Six Sigma, focusing on foundational knowledge of Lean Six Sigma principles․ It equips candidates with the skills to participate in improvement projects and understand key tools like the DMAIC framework and process mapping․ This certification is ideal for those seeking to contribute to quality management initiatives and enhance their problem-solving abilities, while also advancing their careers in various industries․

Importance of Preparation for the Yellow Belt Exam

Preparation is crucial for success in the Yellow Belt exam, as it ensures a solid understanding of Six Sigma principles and tools․ Utilizing study guides, practice exams, and sample questions helps familiarize candidates with the exam format and content․ Regular review of key concepts, such as the DMAIC framework and process mapping, enhances problem-solving skills․ Additionally, time management and effective study strategies are essential to cover all topics comprehensively․ Adequate preparation not only boosts confidence but also increases the likelihood of passing the exam, enabling individuals to contribute effectively to process improvement initiatives and advance their careers in quality management․

Structure and Format of the Yellow Belt Exam

The Yellow Belt exam typically consists of multiple-choice questions, true/false statements, and fill-in-the-blank exercises․ It may also include case study-based scenarios and mathematical problems․ Candidates usually face between 50 to 100 questions, with a time limit of 2 to 3 hours․ The exam format is primarily paper-based or online, depending on the certification body․ A passing score often requires answering at least 70% of the questions correctly․ Understanding the exam structure and format is vital for effective preparation, as it allows candidates to allocate time wisely and focus on key areas of knowledge․ Proper familiarization with the format ensures a smoother test-taking experience․

Key Concepts Covered in Six Sigma Yellow Belt Exam

The exam covers Lean Six Sigma principles, the DMAIC framework, process mapping, statistical tools, and problem-solving techniques, ensuring a solid foundation in quality improvement methodologies․

Understanding the Basic Principles of Lean Six Sigma

Lean Six Sigma combines Lean methodologies with Six Sigma tools to eliminate waste and defects in processes․ It focuses on delivering near-perfect products and services by minimizing variability․ The DMAIC framework—Define, Measure, Analyze, Improve, and Control—is central to this approach․ Candidates learn to identify and address process inefficiencies, leveraging statistical tools and data-driven decision-making․ The philosophy emphasizes continuous improvement and customer satisfaction, ensuring that processes align with organizational goals․ By mastering these principles, individuals can contribute to operational excellence and sustainability in their organizations․ This foundational knowledge is crucial for Yellow Belt certification and effective participation in improvement projects․

The DMAIC Framework and Its Application

The DMAIC (Define, Measure, Analyze, Improve, Control) framework is the cornerstone of Six Sigma methodologies, guiding structured process improvement efforts․ In the Define phase, projects are scoped, and goals are established․ The Measure phase involves data collection to understand current performance․ During Analyze, root causes of defects are identified using statistical tools․ The Improve phase focuses on implementing solutions, while Control ensures sustainability through monitoring and documentation․ This framework is widely applied in Lean Six Sigma to address inefficiencies and achieve operational excellence․ Mastery of DMAIC is essential for Yellow Belt certification, as it equips individuals to lead or support improvement initiatives effectively․

Process Mapping and Flowcharting Techniques

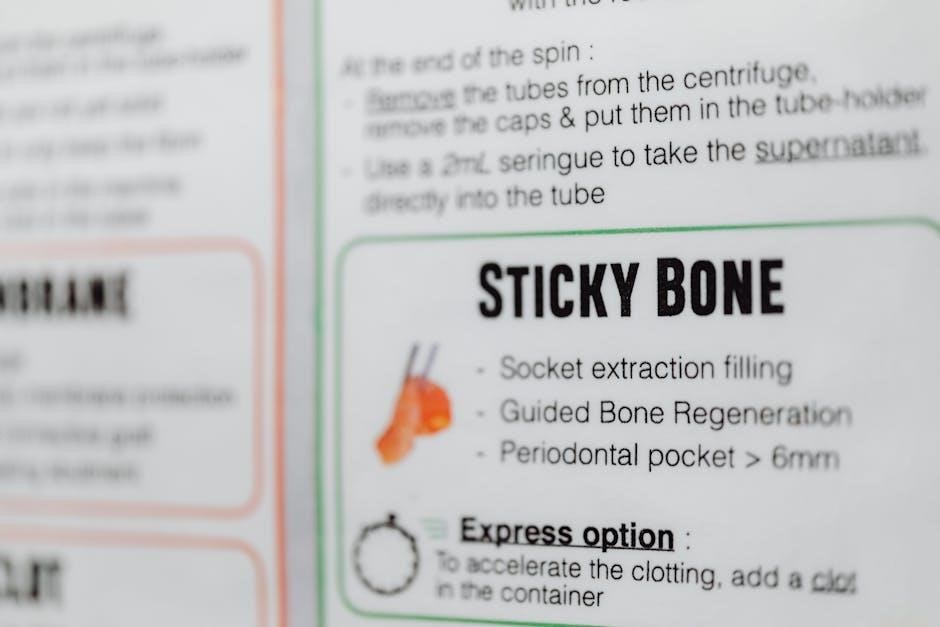

Process mapping and flowcharting are essential tools in Lean Six Sigma for visualizing workflows and identifying inefficiencies․ These techniques allow teams to document and analyze processes step-by-step, making it easier to pinpoint bottlenecks, redundancies, and areas for improvement․ Flowcharts use symbols to represent actions, decisions, and connections, while process maps provide a detailed, sequential overview․ Both tools are integral to the DMAIC framework, particularly in the Analyze phase, where they help uncover root causes of defects․ By standardizing processes and reducing variability, these techniques enable organizations to enhance efficiency, improve quality, and achieve operational excellence․ They are frequently covered in Yellow Belt exam questions to assess understanding of process optimization methods․

Statistical tools and analysis are fundamental in Six Sigma for data-driven decision-making․ Common tools include Pareto charts, histograms, and control charts, which help identify trends, defects, and process variability․ These tools enable teams to analyze data, detect patterns, and make informed decisions․ For instance, Pareto charts highlight the most frequent problems, while histograms reveal data distribution․ Control charts monitor process stability over time․ Understanding these tools is crucial for process improvement and is often tested in Yellow Belt exams․ They are essential for identifying root causes, validating assumptions, and achieving operational excellence, making them a cornerstone of the Six Sigma methodology․

Sample Questions and Answers from the PDF Guide

This section includes multiple-choice, true/false, fill-in-the-blank, and case study-based questions, along with mathematical problems and their step-by-step solutions, aiding candidates in understanding key concepts and exam format․

Multiple-Choice Questions on Six Sigma Fundamentals

These questions cover core concepts such as basic principles, methodologies, and tools used in Six Sigma․ They assess understanding of key terms and foundational knowledge, ensuring candidates grasp the essentials before advancing․ Examples include identifying definitions of Lean Six Sigma, understanding the DMAIC framework, and recognizing process improvement strategies․ Detailed explanations accompany each answer, reinforcing learning and highlighting areas for further study․ This section is crucial for building a strong foundation in Six Sigma, enabling candidates to approach more complex topics with confidence․ Regular practice with these questions helps refine test-taking skills and improves overall exam readiness․

True/False and Fill-in-the-Blank Type Questions

These question types test candidates’ ability to recall and apply specific details about Six Sigma methodologies․ True/False questions assess understanding of key concepts, such as the differences between Lean and Six Sigma or the roles within a project team․ Fill-in-the-blank questions require precise knowledge of terms, definitions, and processes, ensuring candidates can identify critical elements accurately․ Examples include completing statements about the DMAIC framework or defining metrics like DPMO․ These questions help reinforce memory and conceptual clarity, making them an essential part of the exam preparation process․ They also simulate real-world scenarios where precise terminology and understanding are vital for effective communication and problem-solving․

Case Study-Based Questions and Solutions

Case study-based questions present real-world scenarios, requiring candidates to analyze and solve problems using Six Sigma methodologies․ These questions assess the ability to apply tools like process mapping and statistical analysis to identify defects and improve processes․ For example, a case study might describe a manufacturing process with high defect rates, asking candidates to propose solutions using the DMAIC framework․ The PDF guide provides detailed solutions, walking through root cause analysis, process improvements, and outcome measurements․ These questions simulate actual project challenges, helping candidates develop practical problem-solving skills and prepare for real-world applications of Six Sigma principles․ They are essential for evaluating a candidate’s ability to think critically and implement process enhancements effectively․

Mathematical Problems and Their Step-by-Step Solutions

The PDF guide includes a range of mathematical problems tailored to Six Sigma concepts, such as process capability calculations, defect rate analysis, and statistical hypothesis testing․ Each problem is accompanied by a detailed, step-by-step solution, explaining the methodology and tools used to arrive at the answer․ For example, questions might involve calculating sigma levels, determining sample sizes, or interpreting control chart data․ The solutions provide clear explanations of formulas and techniques, ensuring candidates understand both the theoretical and practical aspects of the problems․ These exercises help candidates build proficiency in applying statistical tools and analytical methods, essential for success in the Yellow Belt exam and real-world process improvement initiatives․

Preparation Tips for the Yellow Belt Exam

Effective study strategies include setting a structured schedule, focusing on key concepts, and practicing with sample questions․ Utilize recommended resources and allocate time for regular revision to ensure readiness․

Strategies for Effective Study and Time Management

To excel in the Yellow Belt exam, create a structured study plan focusing on key concepts like DMAIC and process mapping․ Allocate specific time slots for each topic and prioritize areas where improvement is needed․ Utilize active learning techniques, such as self-quizzing and flashcards, to reinforce knowledge retention․ Regularly practice with sample questions to familiarize yourself with the exam format and timing․ Incorporate breaks to avoid burnout and maintain focus․ Additionally, join study groups or forums for collaborative learning and peer support․ Consistent revision and a disciplined approach will ensure thorough preparation and confidence for the exam․

Recommended Resources and Study Materials

For effective preparation, utilize the Six Sigma Yellow Belt Refresher Course, a 158-page document offering in-depth insights and practical examples․ Additionally, the 100 Sample Exam Questions guide provides realistic scenarios to familiarize yourself with the exam format․ The Lean Six Sigma Training by GoLeanSixSigma․com is another valuable resource, available as a free PDF, covering foundational concepts․ Practice exams, such as the IASSC Lean Six Sigma ‒ Yellow Belt with a 93․6% pass rate, are essential for assessing readiness․ These resources, combined with dedicated study, will enhance your understanding of Six Sigma methodologies and improve your chances of success on the exam․

Practice Exams and Their Role in Assessment

Practice exams play a crucial role in assessing readiness for the Six Sigma Yellow Belt certification․ Resources like the IASSC Lean Six Sigma ‒ Yellow Belt Exam, boasting a 93․6% pass rate, offer realistic questions to simulate actual test conditions․ These exams include multiple-choice, true/false, and case study-based questions, mirroring the official exam format․ By attempting these, candidates can identify weak areas, refine their problem-solving skills, and build confidence․ Additionally, free practice exams from platforms like GoLeanSixSigma․com provide hands-on experience with Lean Six Sigma tools and methodologies․ Regular practice helps candidates master time management and reduces exam-day anxiety, ensuring they are well-prepared for the challenges of the certification exam․

Common Mistakes to Avoid During Preparation

During preparation for the Six Sigma Yellow Belt exam, candidates often make avoidable mistakes․ One common error is neglecting to practice with sample exams, which are crucial for familiarizing oneself with the exam format and timing․ Another mistake is focusing solely on memorization without understanding the underlying concepts․ Candidates should also avoid procrastination and ensure consistent study․ Additionally, some may overlook the importance of understanding statistical tools and process mapping, which are critical for problem-solving․ By addressing these pitfalls and adopting a structured study approach, aspiring Yellow Belts can enhance their readiness and confidence for the certification exam․

Benefits of Six Sigma Yellow Belt Certification

Enhances career growth, improves problem-solving skills, and equips individuals to contribute effectively to organizational excellence and efficiency․

Enhanced Career Opportunities in Quality Management

Obtaining a Six Sigma Yellow Belt certification significantly boosts career prospects in quality management․ It demonstrates expertise in process improvement and data-driven decision-making, making professionals highly sought after in industries like manufacturing, healthcare, and finance․ Certification holders are often considered for roles such as quality analysts, process improvement specialists, and project managers․ Employers value Yellow Belt certification as it indicates a strong foundation in Lean Six Sigma methodologies, enabling individuals to contribute effectively to operational excellence․ This credential also positions professionals as competitive candidates for advanced roles, such as Green Belt or Black Belt, and often leads to higher salary potential and greater job satisfaction in quality management fields․

Improved Problem-Solving and Analytical Skills

The Six Sigma Yellow Belt certification enhances problem-solving and analytical skills by teaching individuals how to identify, analyze, and resolve process inefficiencies․ Through exposure to tools like statistical analysis and process mapping, professionals learn to approach problems systematically․ The certification emphasizes data-driven decision-making, enabling individuals to base their solutions on factual insights rather than assumptions․ These skills are highly transferable across industries, allowing Yellow Belt holders to tackle real-world challenges effectively․ By mastering these methodologies, individuals can contribute to continuous improvement initiatives and deliver measurable results, fostering a culture of excellence within their organizations․ This skill set is invaluable for personal and professional growth in quality management and beyond․

Contribution to Organizational Excellence and Efficiency

Earning a Six Sigma Yellow Belt certification enables individuals to contribute meaningfully to organizational excellence and efficiency․ By mastering Lean Six Sigma tools and methodologies, professionals can identify inefficiencies, propose data-driven solutions, and implement improvements that reduce waste and enhance productivity․ This certification equips employees to play a key role in driving continuous improvement initiatives, fostering a culture of operational excellence․ Organizations benefit from Yellow Belt holders’ ability to streamline processes, improve quality, and achieve measurable results․ Their contributions align with strategic goals, ensuring sustained efficiency and competitiveness in the marketplace․ This collaboration between skilled individuals and organizational objectives creates a powerful framework for long-term success․